Have you ever wondered why some kitchen knives lose their edge after only a few weeks while others stay sharp for years?

The secret is hidden inside their knife materials and construction—the real science behind every cut.

Whether it’s a chef’s knife, a small paring knife, or a full knife set, every blade performs differently because of how its steel is made, shaped, and balanced.

A kitchen knife is not just a shiny tool. It is a mix of strong metal, heat, and skilled design.

When you understand what your knife is made of, you can choose one that stays sharp, resists rust, and feels easy to hold.

For home cooks and chefs in the United States, this guide will show you how knives are built.You will learn the simple science behind steel and how to buy the right knife with confidence.

Now that we understand knives are engineered for performance, let’s see what they’re really made of — the materials that shape their sharpness and strength.

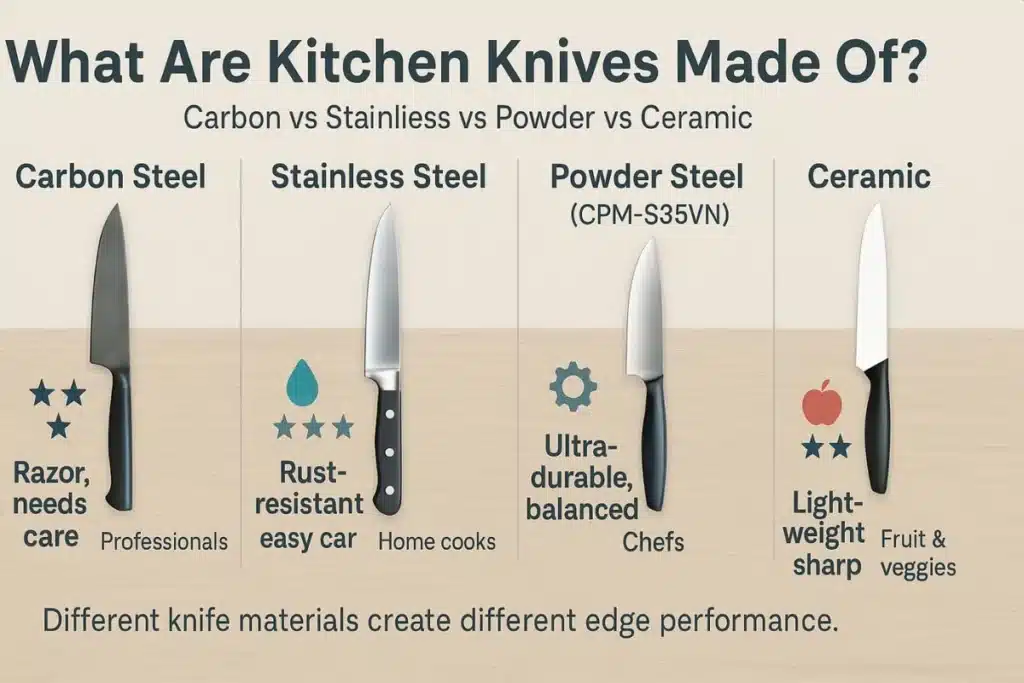

What Are Kitchen Knives Made Of?

Kitchen knives are mostly made from steel and sometimes ceramic. Each material changes how sharp, strong, and rust-resistant a knife will be. Let’s look at the main types and what makes each one different.

1. Carbon Steel — Sharp but Needs Care

Carbon steel gives a knife a very sharp edge and makes sharpening easy.However, it needs proper drying after every wash.If it stays wet, it can rust or form a dark layer called a patina.

Best for: people who don’t mind a little extra care for a very sharp blade.

2. Stainless Steel — Strong and Rust-Resistant

Stainless steel has chromium, which protects the blade from rust and keeps it shiny.It stays clean longer and is common in U.S. kitchens because it’s easy to maintain.You may need more time to sharpen it, but it lasts for years.

Best for: home cooks who want low-maintenance knives.

3. Powder-Metallurgy Steel — Advanced and Durable

Powder steel is made by pressing fine metal powder into a solid blade.This modern process makes it very strong and resistant to wear.It costs more but gives excellent edge retention and durability.

Best for: chefs and buyers who want top-end knives.

4. Ceramic Knives — Light and Razor-Sharp

Ceramic blades are not metal at all.They stay sharp for months and never rust.Still, they can break if dropped or used on bones.

Best for: cutting fruits, vegetables, and soft foods.

5. High-Carbon Stainless Steel — The Perfect Balance

This type combines the sharpness of carbon steel with the rust resistance of stainless steel.It’s the most popular choice for chef’s knives and knife sets in American homes.

Best for: anyone who wants a balanced, long-lasting kitchen knife.

Quick Comparison Table

| Material | Sharpness | Rust Resistance | Durability | Care Needed |

| Carbon Steel | ★★★★★ | ★★☆☆☆ | ★★★★☆ | High |

| Stainless Steel | ★★★★☆ | ★★★★★ | ★★★★☆ | Low |

| Powder Steel | ★★★★★ | ★★★★★ | ★★★★★ | Low |

| Ceramic | ★★★★★ | ★★★★★ | ★★☆☆☆ | Medium |

In Short:Carbon makes knives sharper.Chromium keeps them from rusting.Modern forging brings strength and balance.

That’s why most kitchen knives today are made from high-carbon stainless steel—ideal for both home cooks and professional chefs in the United States.

Once you know what knives are made of, the next step is learning how different steels behave. Each one tells a story of balance between hardness and flexibility.

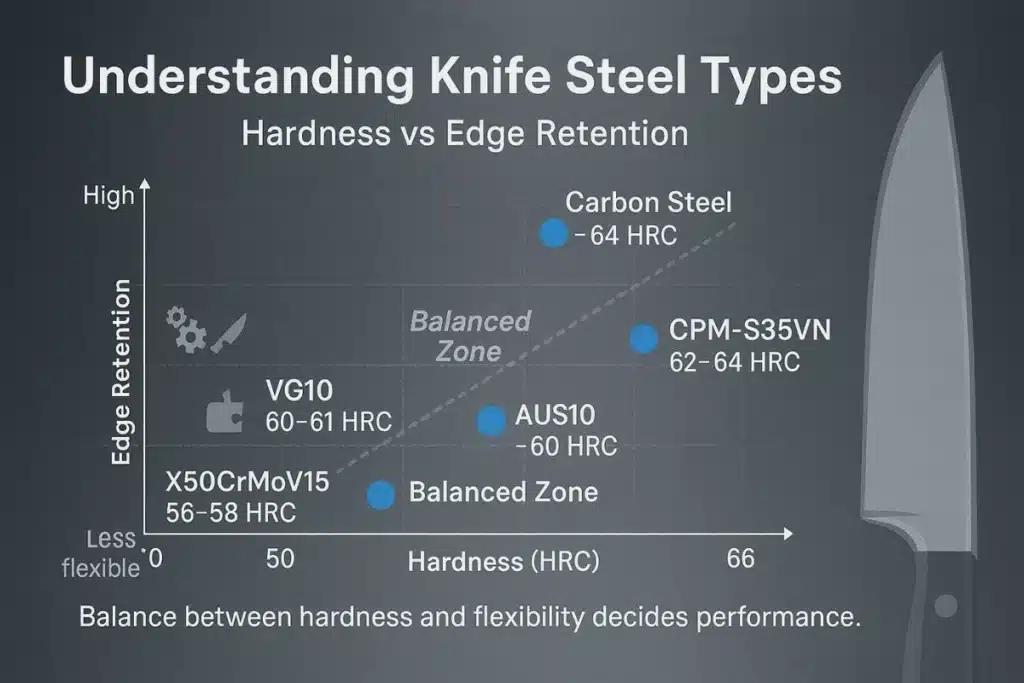

Understanding Knife Steel Types (Carbon, Stainless, and Powder Metallurgy)

Knife steel types decide how long your knife stays sharp and how well it fights rust.

Every type of steel balances four key traits — hardness, toughness, corrosion resistance, and edge retention.

A great kitchen knife doesn’t just “stay sharp.”

It manages the balance between being hard enough to hold an edge and tough enough to avoid chipping.

Steel Types and Their Key Differences

| Steel Type | Hardness (HRC) | Edge Retention | Corrosion Resistance |

| Carbon Steel | 60–64 | Excellent | Low |

| Stainless (X50CrMoV15) | 55–58 | Medium | High |

| VG10 (Japanese) | 59–61 | Very High | High |

| Powder Metallurgy (CPM-S35VN) | 61–63 | Excellent | Excellent |

Each type has its own composition, strengths, and care level.

1. Carbon Steel — Sharp but Reactive

Carbon steel contains about 0.8–1.0% carbon and very little chromium.It gives you a razor-sharp edge and makes sharpening easy.However, it can rust or darken if not dried after use.

Best for: chefs who want maximum sharpness and don’t mind extra care.

2. Stainless Steel — Balanced and Rust-Resistant

Stainless steel has 13–15% chromium, which protects it from moisture and acids.It may not be as sharp as carbon steel, but it lasts longer and needs less maintenance.Brands like Wüsthof and Victorinox use this steel in many U.S. kitchen knives.

Best for: home cooks who prefer easy cleaning and durability.

3. VG10 and AUS10 — Japanese Precision Steels

Japanese steels like VG10 and AUS10 mix carbon (~1%), chromium (~15%), and vanadium.

This blend creates blades that are very sharp, rust-resistant, and long-lasting.

Their Damascus patterns make them both stylish and functional.

Best for: cooks who value beauty and high performance.

4. Powder-Metallurgy Steel (CPM-S35VN) — High-Tech Power

Powder steels are made by pressing fine metal particles at high temperature and pressure.

This process creates a fine grain structure that boosts strength, durability, and edge retention.They cost more but deliver professional-grade performance.

Best for: chefs who want knives that last for decades.

Quick Chemical Comparison

| Type | Carbon (C%) | Chromium (Cr%) | Strength | Typical Use |

| Carbon Steel | 0.8–1.0 | <1 | Very High | Professional knives |

| Stainless Steel | 0.5 | 13–15 | High | Everyday kitchen knives |

| VG10 / AUS10 | ~1 | ~15 | Very High | Japanese knives |

| Powder Steel (CPM-S35VN) | ~1.4 | 14–16 | Extreme | Premium knives |

In Short:Carbon gives sharpness.Chromium prevents rust.Powder metallurgy adds strength and balance.

For most American cooks, tempered stainless steel blends (like Wüsthof or Victorinox) offer the perfect mix of sharpness, safety, and value. If you want the sharpest edges and Japanese artistry, VG10 and AUS10 are top choices.

Different steels need different shaping methods. Let’s look at how forging and stamping affect balance, weight, and overall knife feel.

Forged vs Stamped Knives — Does It Really Matter?

Forged vs stamped knives differ mainly in how they are made.Forged knives are shaped under heat and pressure, while stamped knives are cut from a flat sheet of steel.Both can perform well — but they feel and behave differently in the kitchen.

1. Forged Knives — Strong, Balanced, and Classic

Forged knives are made when a solid piece of steel is heated, hammered, and shaped by hand or machine.

This process strengthens the metal and creates a thicker spine for better balance and control.

Most forged knives include a bolster — the thick part between the blade and handle — which adds safety and weight.They are usually heavier, more durable, and often more expensive.

Best for: professional chefs or users who want long-lasting, perfectly balanced knives.

2. Stamped Knives — Light, Flexible, and Affordable

Stamped knives are machine-cut from large steel sheets, then heat-treated and sharpened.

They lack a bolster, which makes them lighter and easier to handle for long prep sessions.

Modern stamped knives (like those from Victorinox or Mercer) are much stronger than older versions and can match forged knives in daily use.They also cost less and are easier to replace.

Best for: home cooks who want lightweight, budget-friendly knives that still perform well.

So, Does It Really Matter?

Yes — but not as much as the marketing often claims.

A forged knife feels solid and heirloom-quality; a stamped knife feels light and fast.

Both can serve you for years if they are well heat-treated and properly maintained.The best choice comes down to comfort, balance, and personal preference, not hype.

In Short:

- Forged = Strength + Balance + Tradition

- Stamped = Light + Affordable + Practical

- Both can be excellent when made from quality steel and heat-treated correctly.

Now that we’ve compared forged and stamped knives, it’s time to see how a knife actually comes to life — from raw steel to a polished cutting edge.

How Kitchen Knives Are Made — From Steel to Sharp Edge

Kitchen knives are made through a six-step process that cuts, heats, and sharpens steel into a strong cutting tool.

The method combines traditional metalwork with modern CNC precision to make blades that stay sharp and well balanced.

Step 1: Blanking — Cutting the Blade Shape

A flat steel sheet is cut into the rough outline of the knife.This stage, called blanking, creates the base for both forged and stamped blades.

Step 2: Forging or Stamping — Shaping the Metal

Forged knives are heated and hammered, giving them tighter grain and strength.

Stamped knives are machine-cut, making them lighter and easier to mass-produce.

Step 3: Heat Treatment — Hardening the Blade

The blade is heated to about 1,000 °C (1,832 °F) and cooled quickly — a step called quenching. It’s like curing concrete: this builds hardness and stability. Tempering follows to restore toughness so the edge won’t chip.

Step 4: Grinding and Sharpening — Defining the Edge

Precision grinding wheels or CNC machines shape the edge angle.Each pass removes thin layers of steel, setting the knife’s sharpness, balance, and edge retention.

Step 5: Polishing and Finishing — Adding Protection

The surface is polished for a smooth, reflective look.Manufacturers often add anti-corrosion coatings to stop rust and stains. Finally, the handle is fitted and balanced for comfort.

Step 6: Quality Check — Testing Strength and Balance

Every knife is tested on the Rockwell Hardness Scale (HRC).Blades between 55 and 66 HRC offer the best mix of hardness and flexibility.Inspectors confirm sharpness, finish, and weight before shipping.

In Short:Kitchen knives are made through blanking, forging, heat-treating, grinding, polishing, and testing.

Each step strengthens the steel and shapes the perfect edge. That’s how a plain sheet of metal becomes a precise kitchen tool used by cooks worldwide.

The blade’s outside is only half the story. What lies inside the handle — the tang — decides how steady and balanced the knife feels in your hand.

Full Tang vs Partial Tang — The Hidden Design That Shapes Balance

The difference between full tang and partial tang knives is how far the blade’s steel runs inside the handle.

A full tang knife has steel running through the entire handle for maximum balance and strength, while a partial tang knife extends only partway, making it lighter and easier to handle.

1. Full Tang Knives — Strong, Safe, and Balanced

A full tang knife carries a single piece of steel from the tip of the blade to the end of the handle.

You can often spot a thin metal strip between the handle scales — proof of its solid build.

This design improves balance, durability, and control when cutting dense foods.

Pros:

- Excellent balance and stability

- Long-lasting strength

- Safer for heavy chopping and professional use

Cons:

- Heavier than partial tang

- Usually more expensive

Best for: chefs and regular home cooks who want precision and long life.

2. Partial Tang Knives — Light, Easy, and Affordable

A partial tang knife has its steel extending only partway into the handle.It’s lighter, less costly, and great for everyday slicing.

Modern versions, when well riveted and heat-treated, can still perform impressively in the kitchen.

Pros:

- Lightweight and easy to use

- More affordable

- Ideal for travel or quick food prep

Cons:

- Slightly less durable

- Can loosen if poorly built

Best for: beginners, casual cooks, or travelers.

Comparison Table

| Feature | Full Tang | Partial Tang |

| Steel Extension | Through entire handle | Stops midway inside |

| Balance | Excellent | Moderate |

| Durability | Very High | Medium |

| Weight | Heavier | Lighter |

| Ideal Use | Heavy chopping, daily cooking | Quick prep, travel sets |

Which Should You Choose?

If you often cut dense vegetables or meat, a full tang will feel steadier and more secure.

For light cooking, travel knives, or small prep work, a partial tang works fine — just check that the handle is firmly riveted.

In Short

- Full tang = Strength, Balance, and Safety

- Partial tang = Light Weight, Low Cost, and Easy Handling

Both types work well when made from quality steel and solid handle construction. Learn how to store and protect both types in our knife safety tips and storage guide.

Once the structure is set, hardness becomes the next big question. How do we measure the strength of that steel? That’s where the Rockwell Scale comes in.

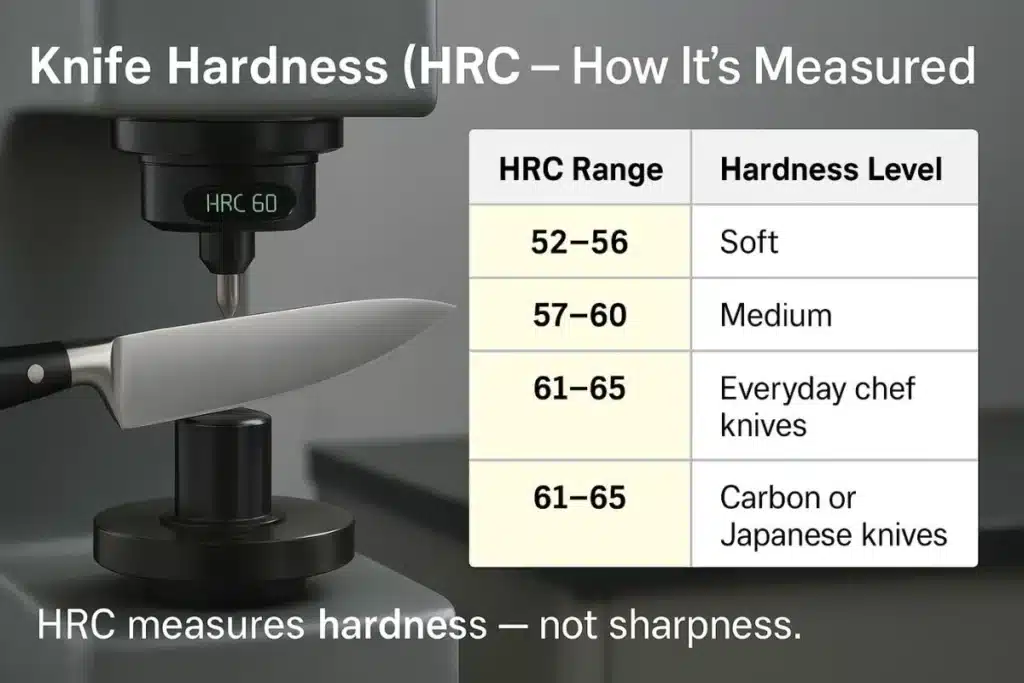

What Is the Rockwell Hardness Scale (HRC) in Kitchen Knives?

The Rockwell Hardness Scale (HRC) measures how hard a knife’s steel is and how well it resists wear or deformation.

In simple words, it shows how long a knife can stay sharp before dulling.A higher number means harder steel — but not necessarily a sharper edge.

How Does the Rockwell Scale Work?

Manufacturers use a Rockwell hardness tester to measure how deep a diamond-tipped cone presses into the steel.If the cone makes a shallow mark, the steel is hard. If it sinks deeper, the steel is softer.

This test gives a number, called the HRC rating, that shows how strong and wear-resistant the metal is.

What Is the Ideal HRC Range for Kitchen Knives?

Most kitchen knives fall between 52 and 65 HRC, balancing sharpness, toughness, and durability.

| HRC Range | Common Use | Sharpness | Durability |

| 52–56 | Soft stainless steel | Easy to sharpen | Dulls faster |

| 57–60 | Balanced steel | Excellent edge retention | Good toughness |

| 61–65 | Premium or carbon steel | Razor sharp | Can chip if misused |

Knives around 55–60 HRC are ideal for most home cooks.They sharpen easily but still hold a steady edge for daily use.

Which Knife Steels and Brands Match These HRC Levels?

- Victorinox (56–58 HRC) — Balanced edge and easy care for home kitchens.

- VG10 or AUS10 (60–61 HRC) — Japanese steels known for long-lasting sharpness.

- CPM-S35VN (62–64 HRC) — Powder-metallurgy steel used in premium chef knives.

Each steel type offers a unique trade-off between edge retention, toughness, and ease of sharpening.

Does a Higher HRC Mean a Sharper Knife?

No — this is a common myth.

A higher HRC means the knife stays sharp longer, not that it feels sharper when new.

Actual sharpness depends on the edge angle, grind, and how well it’s sharpened.

In Short Understanding HRC in Knives

- HRC measures hardness, not sharpness.

- Higher HRC = longer edge life, but more care needed.

- 55–60 HRC suits most home cooks.

- 60+ HRC is for professionals or enthusiasts seeking extreme edge retention.

Want to keep your knife performing at its best? Check our knife sharpening and maintenance Guide for simple steps on how to sharpen safely and extend your blade’s life.

Hardness defines endurance, but coatings decide protection. Let’s explore the invisible layers that keep your blades smooth and rust-free.

What Are Knife Coatings and Surface Treatments?

Knife coatings are thin protective layers applied to a blade to improve durability, rust resistance, and cutting performance.

These advanced surface treatments help knives stay sharper longer, glide more smoothly, and resist stains from acidic foods.

They work like invisible armor, protecting the metal from oxidation, scratches, and corrosion.

How Does Cryogenic Treatment Improve a Knife?

Cryogenic treatment strengthens steel by freezing it to extreme sub-zero temperatures — often below –300°F (–184°C).

This process refines the steel’s micro-grain structure, improving its toughness, stability, and edge retention.

Benefits of Cryo-Treated Knives:

- Makes steel denser and stronger

- Helps blades stay sharp longer

- Reduces risk of chipping or bending

Example: Premium forged knives often include cryo treatment to extend life and performance.

What Is DLC (Diamond-Like Carbon) Coating?

DLC coating adds a thin, carbon-based layer that mimics the hardness of diamond.It gives knives a matte black finish, reduces friction, and prevents scratching during heavy use.

DLC Coating Benefits:

- Increases surface hardness and wear resistance

- Makes cutting smoother

- Adds a premium, anti-stick look

Best For: Professional chefs and precision knives that need both style and performance.

What Is Titanium Nitride (TiN) Coating?

Titanium Nitride (TiN) is a gold-colored, non-reactive coating used to protect knives from rust and food acids. It’s especially useful when cutting citrus or tomatoes, where uncoated steel may react.

TiN Coating Benefits:

- Prevents corrosion and discoloration

- Extends blade life

- Adds a golden, high-end appearance

Best For: Everyday kitchen knives used with acidic ingredients.

Comparison: Knife Coatings at a Glance

| Coating Type | Key Feature | Appearance | Ideal Use |

| Cryogenic Treatment | Improves strength and edge retention | Invisible | Forged or high-end knives |

| DLC Coating | Reduces friction and wear | Matte black | Premium or chef knives |

| Titanium Nitride (TiN) | Adds corrosion resistance and color | Golden | General kitchen knives |

Why Are Knife Coatings Important?

Modern knife coatings make blades stronger, longer-lasting, and easier to maintain. They reduce rusting, enhance cutting smoothness, and add distinctive visual appeal.

In short: knife coatings combine metallurgy and nanotechnology to create blades that last longer and look better.

Want your coated knives to stay smooth and shiny for years? Read our knife sharpening and maintenance Guide for easy care tips that protect DLC, TiN, and cryo-treated blades.

Even with the best coatings, knives can still rust if mistreated. Understanding why rust forms helps you keep your blades spotless for years.

Why Do Kitchen Knives Rust — And How Can You Prevent It?

Knives rust when moisture and oxygen react with the steel surface, forming oxidation.

Even stainless steel can rust if exposed to water, acid, or heat for too long.

Rust weakens the blade, causes orange spots, and makes cutting less smooth.

Common Reasons Why Knives Rust

- Moisture exposure: Leaving water, juice, or salt on the blade after use.

- Dishwasher damage: Heat and detergents speed up corrosion and dull the edge.

- Improper storage: Keeping knives in damp wooden blocks or drawers without drying them first.

- Acidic food reaction: Foods like tomato, lemon, or vinegar slowly break down the protective layer.

Quick Fact: “Stainless” means more resistant, not rust-proof.

How to Prevent Knife Rust

Follow these easy care habits to protect your kitchen knives from corrosion:

✅ Hand-wash and dry immediately — don’t air-dry or leave them in the sink.

✅ Oil carbon steel knives with food-safe mineral oil to block moisture.

✅ Avoid soaking knives in water or soap for long periods.

✅ Store knives properly — use a magnetic strip or ventilated knife block.

✅ Wipe fingerprints and water marks after cleaning to prevent oxidation.

If you see light rust spots, gently rub them with a baking soda paste using a soft cloth. This removes rust without scratching the blade.

Things You Should Never Do

🚫 Don’t put knives in the dishwasher.

🚫 Don’t leave them wet or unwashed overnight.

🚫 Don’t use bleach or harsh cleaners — they damage the metal.

These mistakes strip the knife’s natural protective coating and invite oxidation.

In Short: Rust forms when water and oxygen stay on unprotected steel for too long. Keep your knives clean, dry, and lightly oiled, and they’ll stay sharp and rust-free for years.

A knife’s body may be steel, but your comfort depends on its handle. The material you grip decides how safe and enjoyable your cutting experience will be.

What Are Knife Handle Materials and Why Do They Matter?

A knife handle affects grip, comfort, and balance — it decides how safely and easily you can use the blade.The right handle keeps your wrist aligned and reduces fatigue while cutting.

Kitchen knife handles are usually made of wood, micarta, G10, stainless steel, or plastic, and each offers a unique mix of comfort, durability, and maintenance.

Common Knife Handle Materials (With Pros and Cons)

| Material | Grip & Feel | Durability | Care Level | Best For |

| Wood | Warm, classic texture | Medium | Needs oiling to prevent cracks | Traditional users |

| Micarta / G10 | Excellent grip, even when wet | Very High | Low | Professionals |

| Stainless Steel | Smooth, hygienic surface | Very High | Low | Modern kitchens |

| Plastic / Polypropylene | Lightweight, affordable | Medium | Dishwasher safe | Everyday use |

| Composite Handles | Balanced feel, stylish look | High | Minimal | All-rounders |

What Is an Ergonomic Knife Handle?

An ergonomic handle fits the natural curve of your hand. It keeps your wrist straight, distributes weight evenly, and prevents strain after long use.

Good ergonomics = comfort + safety + control.That’s why chefs prefer handles that feel stable and smooth rather than shiny or decorative.

Pro Tip: Always choose a handle that feels right — not just one that looks good.Your comfort determines how safely you cut.

How to Choose the Best Knife Handle

When buying a knife, consider how it feels in your grip:

- For daily cooking: Choose G10 or Micarta for comfort and durability.

- For traditional style: Wood gives warmth and balance but needs more care.

- For easy maintenance: Plastic or stainless steel handles work best.

In Short:

- Knife handles control comfort, grip, and balance.

- Micarta and G10 offer the best all-round performance.

- Wood adds beauty but needs care.

- Always pick based on fit and feel, not just design.

Want your knife handles to last longer and stay spotless? Read our knife safety tips and storage guide to learn how to clean, oil, and protect every handle type safely.

Beyond performance and comfort, modern kitchens now focus on sustainability. Eco-friendly knives prove that strength and ethics can exist side by side.

What Are Eco-Friendly Kitchen Knives?

Eco-friendly kitchen knives are made from recycled steel, renewable wood, and low-energy forging methods that cut down waste and carbon emissions.

They stay sharp, last long, and help protect the planet.

Key Sustainable Materials Used in Kitchen Knives

- Recycled Stainless Steel — Uses less energy and performs like new metal.

- Bamboo Handles — Renewable, lightweight, and biodegradable.

- FSC-Certified Wood — Comes from responsibly managed forests.

- Compostable Composites — Made with plant-based materials that leave less waste.

Simple Tip: Eco materials save both energy and resources without reducing quality.

Examples of Sustainable Knife Brands

| Brand | Eco Feature | Main Benefit |

| Victorinox Greenline | Recycled steel, bio-based handles | Recyclable and durable |

| Shun Green Series | Bamboo handles, low-energy forging | Renewable and stylish |

| Opinel Nature Line | FSC-certified beechwood | Biodegradable and affordable |

These brands prove that green doesn’t mean weak — recycled steel, when heat-treated correctly, performs just like premium alloys.

Why Choose an Eco-Friendly Knife

- Reduces waste and supports ethical manufacturing.

- Made from non-toxic, food-safe materials.

- Looks modern and natural in any kitchen.

- Durable — recycled steel holds an edge for years.

In Short: Eco-friendly kitchen knives combine sharpness, strength, and sustainability.

Made with recycled steel, bamboo, or certified wood, they show that great performance and green values can truly go hand in hand.

Want to go green in your kitchen? Check our Eco-Friendly Knife Buying Guide to compare top sustainable brands and learn simple care tips for long-lasting performance.

From steel and tang to coatings and sustainability, every detail leads to one goal — durability. Let’s sum up what truly makes a knife built to last.

What Makes a Durable Kitchen Knife — The Complete Checklist

A durable kitchen knife is built with high-quality steel, solid tang construction, and moisture-resistant handles that keep it sharp, safe, and long-lasting.

Durability isn’t chance — it’s smart design and care.

Key Factors That Make a Knife Durable

| Factor | Ideal Specification | Why It Matters |

| Steel Type | High-carbon stainless or VG10 | Maintains sharpness and resists rust |

| Tang | Full tang | Prevents handle separation and improves balance |

| Hardness (HRC) | 56–60 | Balances edge retention with flexibility |

| Coating | DLC or Titanium | Adds corrosion protection and reduces wear |

| Handle Material | G10 or Micarta | Strong grip, moisture-proof, and long life |

Quick tip: If your knife meets three or more of these factors, it’s a keeper.

Why Durability Matters

- Longer lifespan: Reduces the need for frequent replacements.

- Safer cutting: Stronger handles and tangs prevent slips or breakage.

- Better control: Balanced weight makes slicing easier and smoother.

How to Maintain Knife Durability

Even durable knives need care:

- Hand-wash only and dry right after use.

- Avoid dishwashers — heat and detergent damage blades.

- Store safely in a ventilated block or magnetic strip.

- Sharpen regularly for consistent edge retention.

In Short: Durable knives combine strong steel, balanced design, and proper maintenance. Look for high-carbon stainless steel, full tang construction, and ergonomic handles.

Ready to upgrade your kitchen setup? Explore our Best Kitchen Knives 2025 Buying Guide for expert picks, durability ratings, and pro recommendations.

You’ve now explored every layer of knife design — materials, hardness, coatings, and care. Let’s wrap up with the most common questions people ask about kitchen knives.

FAQs :knife materials and construction

What is the best material for kitchen knives?

The best material for kitchen knives is high-carbon stainless steel because it keeps a sharp edge and resists rust.

It combines the hardness of carbon steel with the easy maintenance of stainless steel — ideal for both home cooks and professionals who need long-lasting sharpness and balance.

Which is better: carbon steel or stainless steel knives?

Carbon steel stays sharper longer, while stainless steel resists rust and stains better. If you cook daily, high-carbon stainless steel gives you the best of both worlds — long edge. life with easy cleaning. Chefs often prefer carbon for sharpness; home cooks usually go stainless for convenience.

What steel do knives use?

Most kitchen knives use carbon steel, stainless steel, VG10, or powder metallurgy steels like CPM-S35VN.

Each type offers a balance between hardness, corrosion resistance, and edge retention. High-end brands often combine alloys with vanadium or molybdenum for extra strength and smooth cutting.

How are kitchen knives made?

Kitchen knives are made in six main steps: blanking, forging or stamping, heat treatment, grinding, polishing, and testing.

Forged knives are hammered for strength; stamped knives are machine-cut for precision.

Each stage strengthens the steel and shapes a balanced, sharp blade ready for the kitchen.

What is a full tang knife?

A full tang knife means the steel runs through the entire handle. This design gives better balance, control, and durability — perfect for chopping and heavy cutting. You can spot it by a visible steel line between handle scales, a sign of solid construction.

What does HRC mean in knives?

HRC stands for Rockwell Hardness Scale, which measures how resistant a blade is to deformation.Most kitchen knives fall between 55–65 HRC.

A higher number means better edge retention but lower flexibility — so 58–60 HRC is ideal for balanced use.

Why do knives rust even if they’re stainless?

Stainless knives can still rust if left wet or dirty.

“Stainless” means more rust-resistant, not rust-proof.

Moisture, salt, and food acids attack the surface over time — that’s why handwashing and drying immediately keeps blades spotless.

What are knife coatings like DLC and titanium used for?

Knife coatings such as Diamond-Like Carbon (DLC) or Titanium Nitride (TiN) protect the surface from corrosion and scratches.

They also reduce friction, helping knives glide through food smoothly while adding a stylish black or golden finish.

Are eco-friendly knives durable?

Yes, eco-friendly knives made from recycled steel, bamboo, or FSC-certified wood are highly durable when heat-treated correctly.

Modern green materials can match the performance of traditional knives while reducing energy waste and environmental impact.

What makes a kitchen knife durable?

A durable knife combines high-carbon stainless steel, a full tang, HRC between 56–60, and a moisture-resistant handle like G10 or Micarta.

When properly maintained, such knives can last decades without losing balance or sharpness.